Lansu: Common faults in laser marking machine when marking characters

Lansu: Common faults in laser marking machine when marking characters

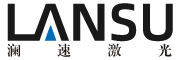

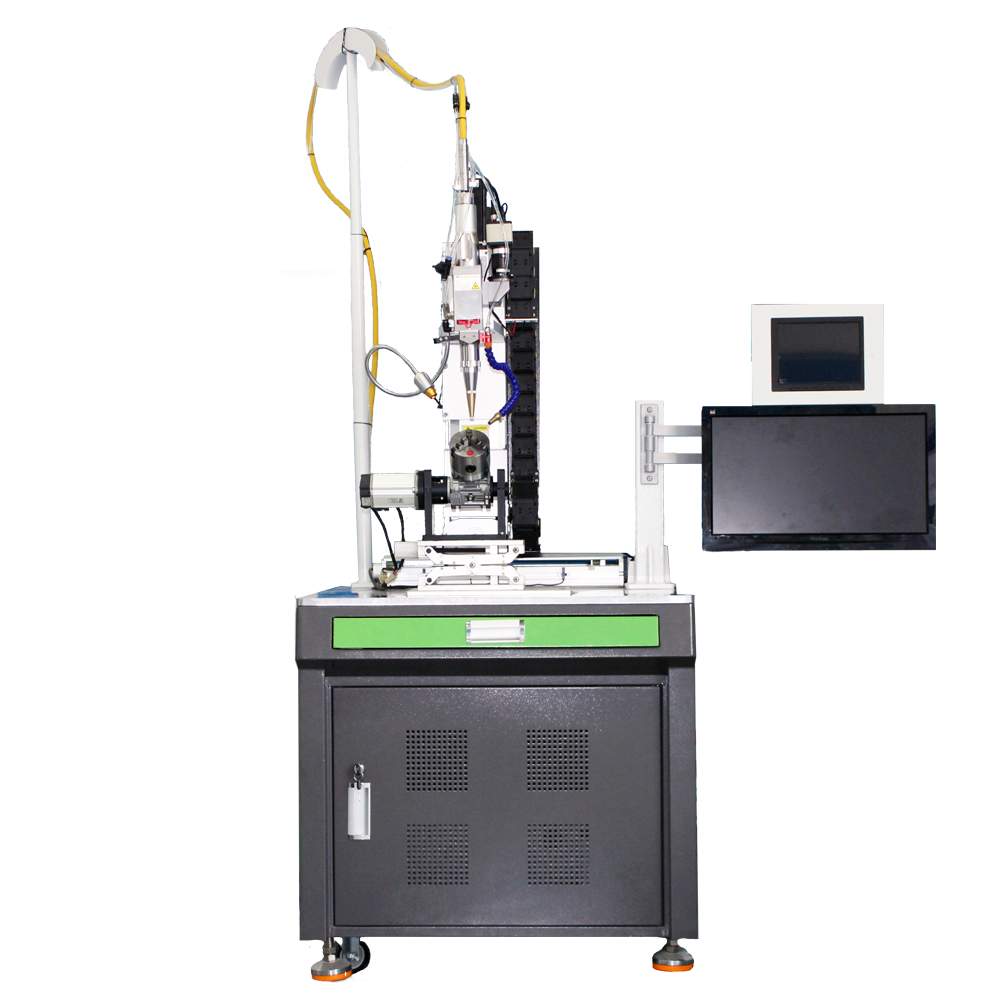

The laser marking machine has powerful functions.It can not only perform simple marking character patterns on the surface of the workpiece, but also can peel paint, punch or hollow engraving on the product. It is widely used. It is a highly automated laser device that can continuously 24 hours operation. However, after all, laser marking machines are mechanical equipment, and many device accessories are complex and precise. Sometimes they may cause some problems due to operation errors or other reasons. Here are some problems that are easy to occur when marking characters:

1. The laser marking machine has uneven typing:

The level is not adjusted, that is, the laser galvanometer lens or field lens is not parallel to the processing table, because the two are not the same degree, which will cause the length of the laser beam to reach the processed object after passing through the field lens. The laser will fall on the The energy on the processed object will show a non-different energy density, and at this time, the effect on the metal will be uneven. Before using the equipment, adjust the level of the machine in advance and make the laser vibration lens or field lens parallel to the processing table.

2, the laser marking machine can not print:

If F2 is unable to mark, it may be a machine failure.

① The software laser type is set incorrectly

② The light path is wrong

③Laser power is not powered or damaged

④ The control signal wire is broken or the plug is loose or the control card is broken

⑤ The laser is broken.

3. The marking pattern of the laser marking machine is partially unclear:

① Solution: Check whether the thickness of the mold plate is uniform, whether the mold pressure is too small, whether the temperature is too low, and whether the accuracy of the machine is reduced.

② Process control points: The thickness error of the stamping plate should be controlled at 0. Within O01mm, the hardness should be maintained at 230-280N / mm. Because the hologram is embossing interference fringes by applying a certain pressure to the embossing roller, if the hardness of the embossing plate is insufficient, internal stress will deform or damage the embossing plate during the imprinting process.